Turntide to debut breakthrough axial flux EDU at CONEXPO

By Marie Carter-Robb • Posted in Engineering

Turntide Technologies, a leader of best-in-class electric motors, power electronics, and energy storage, will unveil the breakthrough Turntide Axial Flux Electric Drive Unit (EDU) during CONEXPO-CON/AGG, North America’s largest construction trade show, which takes place once every three years and returns to Las Vegas from 3 – 7 March 2026.

The company says the Axial Flux EDU enables electric and hybrid system manufacturers of any size to move from concept to vehicle in as little as eight months. By delivering a fully validated, configurable and scalable platform, Turntide claims it can remove months, if not years, of component-level testing, cutting both time and cost to market.

Manufacturers are increasingly moving away from sourcing separate motors, power electronics and gearing or differential systems from multiple suppliers, instead opting for fully integrated electric propulsion systems. This shift is driven by the need to reduce time and cost to market, improve efficiency, accommodate higher voltage systems and make better use of limited packaging space. With validation of individual motors, inverters and power electronics often taking months or years, Turntide says its pre-validated EDU platform significantly reduces that burden, helping original equipment manufacturers simplify and accelerate new or enhanced product development.

“We’ve created a highly configurable and scalable EDU that easily fits into a wide range of applications from high-performance recreation vehicles to electric construction equipment,” said Steve Hornyak, Turntide CEO. “By handling the integration, validation, and testing upfront, our EDU decreases the risk, time and cost of bringing new products to market.”

Battle-tested technology

Turntide recently raced its Sierra Echo-R at King of the Hammers, one of the harshest off-road races globally. Powered by the Turntide Axial Flux EDU platform, the Sierra Echo-R became the first purpose-built electric vehicle to qualify for and compete in the King of the Hammers Desert Challenge course.

Designed to push drivetrain limits under sustained vibration, load, dirt, dust and heat, the event provided a real-world proving ground for the EDU’s performance. The vehicle completed more than 600 miles of demanding desert terrain with no reported issues.

Insights from the Desert Challenge are influencing further development of the Axial Flux EDU, which is designed to simplify integration and accelerate deployment across off-highway applications, including high-performance powersports, heavy construction equipment, automotive and other off-highway applications.

Modular performance in a compact package

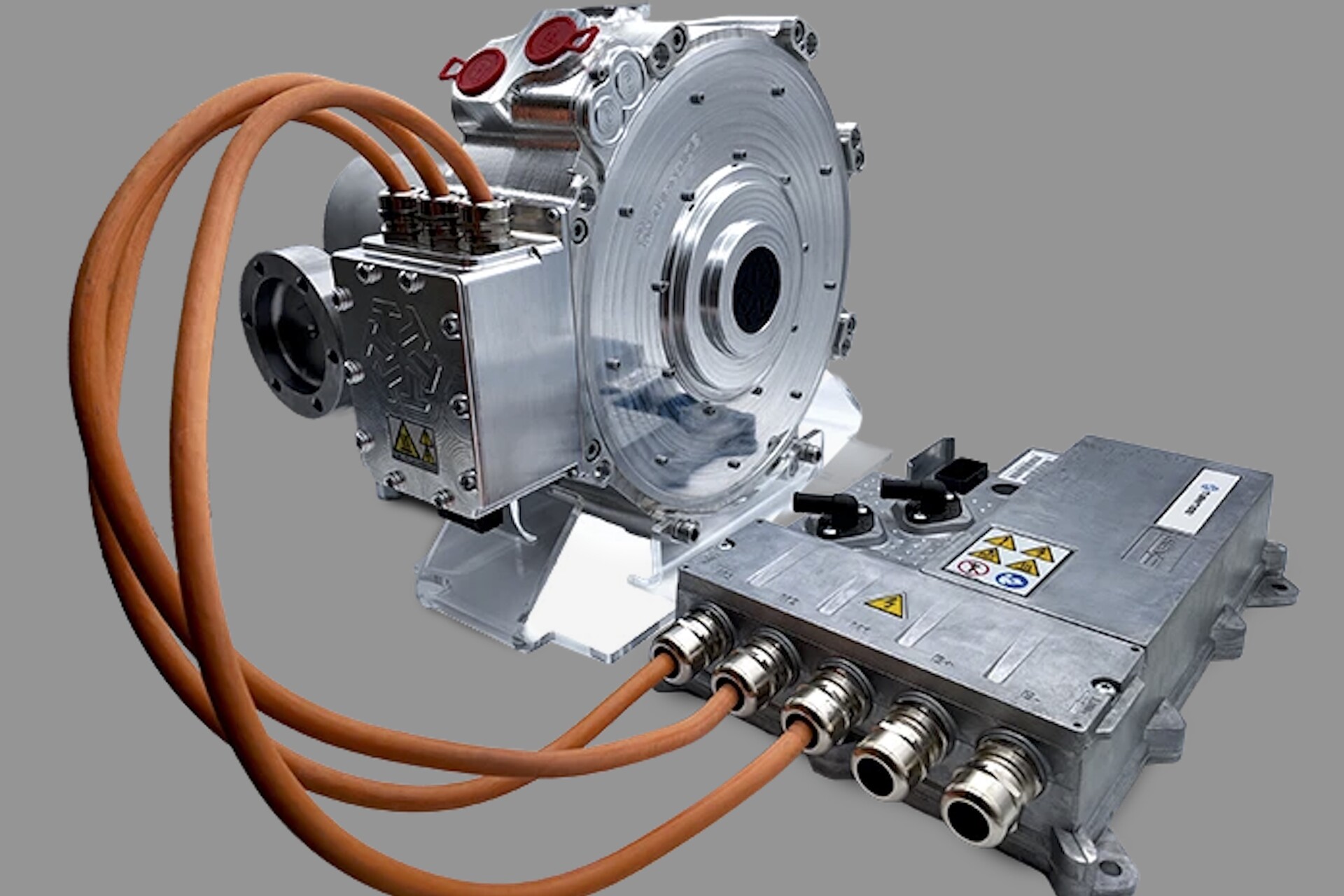

The Turntide Axial Flux EDU is a modular platform designed to scale across a wide range of vehicle and equipment architectures while lowering total cost of ownership.

Compared to a radial flux motor, the axial flux EDU delivers 53% higher torque density, with 58% less size and 37% less weight, providing OEMs with a highly efficient, space-saving solution for electrified and hybrid vehicles.

The platform supports 400 volts and higher, with single or stacked axial flux motor options. Power ranges from 73 kW to 220 kW nominal, and from 300 kW to 700 kW peak, enabling scalability to meet diverse customer requirements.

High torque and power density within a compact form factor reduce overall vehicle weight and free up space to pair the EDU with a larger battery for extended range. Vehicles can also operate more precisely at slower speeds.

Low-speed, high-torque performance enables the use of less complex gear design, delivering performance improvements, reduced mechanical complexity, lower weight, improved reliability, cost savings and easier integration and maintenance.

The motor and inverter share the same cooling system, simplifying integration while maintaining performance. The system is also designed for independent serviceability, allowing individual components to be serviced separately to reduce downtime and lower maintenance costs.

Major applications for the Turntide Axial Flux EDU include powersports and recreation vehicles, construction equipment, off-highway vehicles and equipment, commercial vehicles and automotive.