MPI Raises the Heat on Innovation with New 1600°C XRD Capability

By Marie Carter-Robb • Posted in Manufacturing

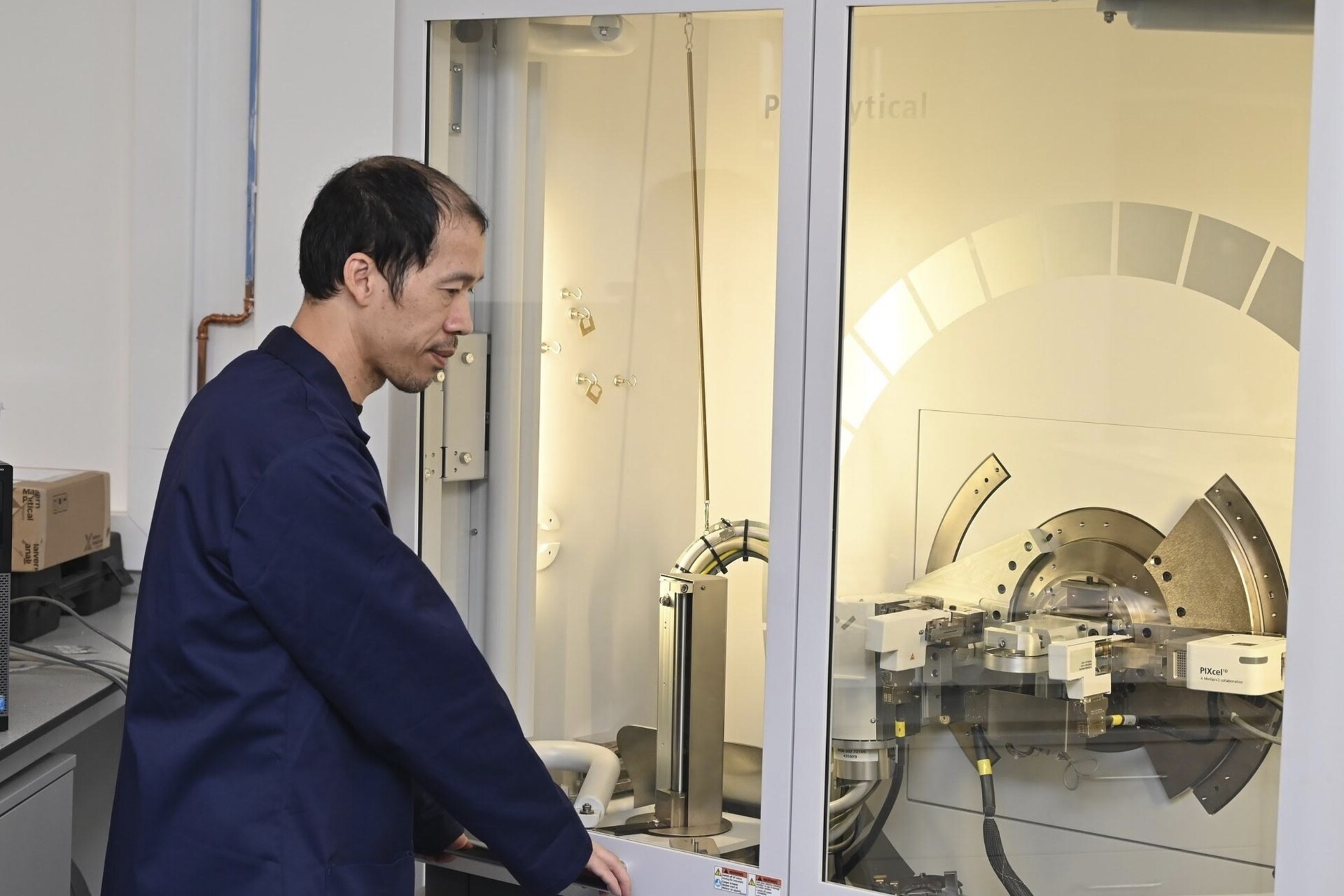

The Materials Processing Institute (MPI) has developed a new high-temperature X-ray Diffraction (XRD) capability, enabling researchers and industrial partners to examine how materials behave under extreme temperatures.

This advancement positions Middlesbrough-based MPI among a select group of UK facilities able to offer in-situ high-temperature XRD analysis up to 1600°C for both industrial and academic clients.

The capability allows real-time observation of phase transformations in ceramics, slags, minerals and metal alloys, replicating conditions found in processes such as casting, foundry operations, and high-temperature kilns.

It has been delivered through the PRISM research programme, funded by Innovate UK, which supports innovation, productivity, and sustainability across the UK metals and steel sector as it transitions toward net-zero and circular-economy practices.

Demand for in-situ XRD analysis from ambient temperatures up to 1600°C – hotter than most volcanic lava – is increasing, as manufacturers and researchers seek deeper understanding of phase changes during heating and cooling.

MPI’s existing platinum hot stage supports XRD analysis up to around 1400°C. To extend this capability, researchers at its Advanced Materials Characterisation Centre designed and built a tantalum-based hot stage, delivering stable, accurate measurements at significantly higher temperatures while reducing contamination and wear.

This development significantly enhances MPI’s ability to support clients working with high-temperature materials across a wide range of industrial processes, including steelmaking, metallurgical refining, refractory and furnace lining design, glass and mineral processing, foundry and casting operations, cement and slag manufacture, pyrometallurgy and ore reduction, advanced ceramics and composites, high-temperature additive manufacturing, and applications in the energy, hydrogen, and chemical sectors.

Chris Oswin, CEO of the Materials Processing Institute, said:

“Developing this new high-temperature XRD capability represents a major step forward for UK materials science. By enabling accurate analysis up to 1600°C, we can support industry with insights that were previously out of reach.

“This in-house technology gives manufacturers the confidence to innovate, optimise their processes and understand how materials behave in real-world conditions. It reinforces our commitment to providing world-class research expertise through the PRISM programme.”