Materials Processing Institute awarded £1.86m to extend national PRISM programme

By Marie Carter-Robb • Posted in Manufacturing

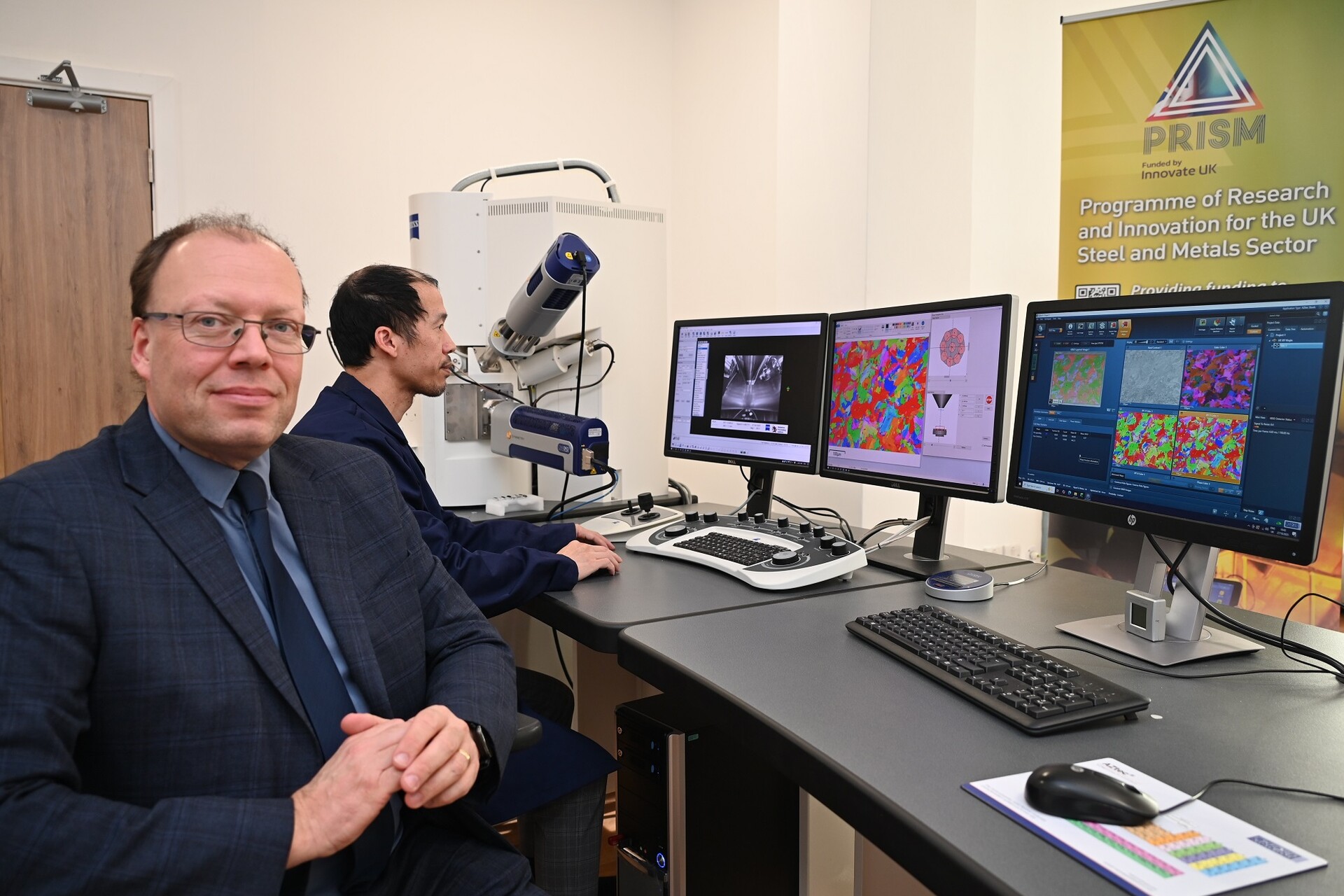

The Materials Processing Institute (MPI) has been awarded £1.86 million in funding from Innovate UK, part of UK Research and Innovation (UKRI), to continue leading the PRISM programme – a flagship national initiative driving innovation, productivity, and decarbonisation across the UK’s steel and metals sector.

Since its launch in March 2020, the £18 million PRISM programme has supported a broad range of high-impact research and development focused on decarbonisation, digital technologies, and the circular economy. It has delivered investment in new research centres and equipment at MPI’s Teesside headquarters, supporting the commercialisation of new technologies and backing projects that improve industrial competitiveness and productivity.

The new funding will allow MPI to extend its leadership of a diverse portfolio of projects designed to deliver measurable carbon reductions, cost savings, and innovation-led growth. Among these are the further development of MPI’s seven-tonne Electric Arc Furnace, which is strengthening the UK’s steelmaking capabilities and accelerating the move towards low-carbon electric steel production.

Work is also underway to develop low-carbon cement formulations by replacing Ground Granulated Blast-Furnace Slag (GGBS) with more sustainable alternatives, while other projects are focused on harnessing artificial intelligence and machine learning to draw insight from over 80 years of industrial data and optimise processes across the metals sector. In addition, MPI is advancing techniques for critical materials recovery to help establish a secure UK supply of the minerals vital to the green energy transition.

MPI’s leadership of the PRISM programme is already delivering tangible innovation through projects such as the establishment of a hydrogen demonstration facility for testing clean energy applications in steel and allied industries. At its Normanton Steel Plant, the Institute is also deploying Industry 4.0 technologies – including digital twins, smart process controls, data analytics, and remote monitoring – to enhance plant performance and efficiency. In the field of sustainable cement innovation, MPI’s advanced laboratories are being used to explore the reuse of industrial by-products as viable alternatives to traditional clinker-based binders. Meanwhile, its work in powder metallurgy and additive manufacturing is supporting the development of next-generation materials and circular economy solutions.

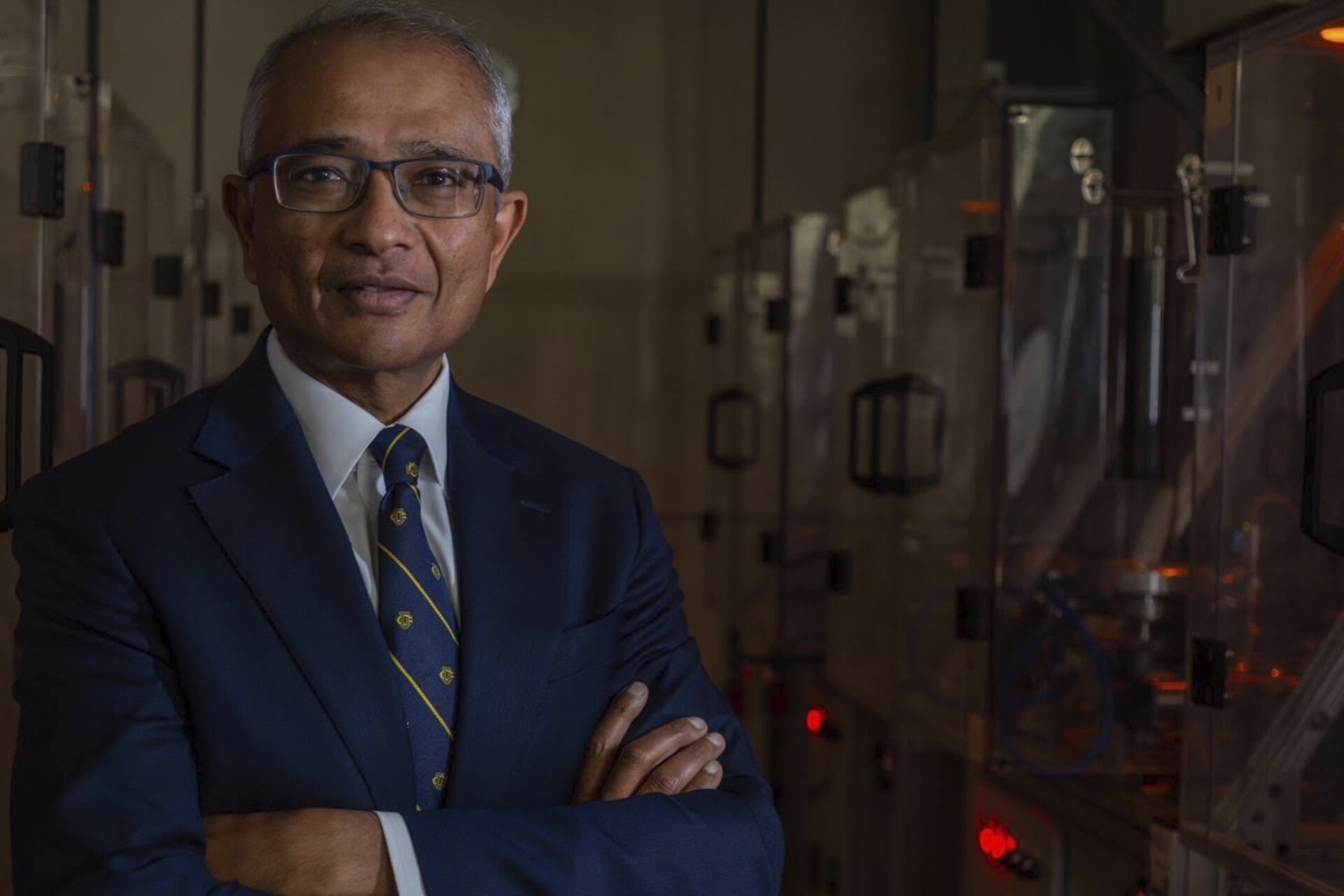

Chris Oswin (pictured), Chief Executive Officer at MPI, said: “This new round of funding enables the UK metals sector to continue delivering innovation to help shape its future. Investment in research, development and innovation means that we are uniquely positioned to lead on breakthrough technologies to improve materials, raise productivity, and develop new production routes, while supporting environmental sustainability and decarbonisation.”