Materials Processing Institute Announces £2.9m Electric Arc Furnace Upgrade

By Marie Carter-Robb • Posted in Manufacturing

The Materials Processing Institute (MPI) has announced a £2.9m upgrade of its seven-tonne Electric Arc Furnace (EAF) to accelerate the development of next-generation green steel technologies.

With key components now on site at its Green Steel Centre in Middlesbrough, installation work on the UK’s only pilot-scale research EAF is set to begin in January.

The upgraded facility will provide a state-of-the-art platform for developing, testing, and refining low-emission steelmaking processes under realistic industrial conditions.

By bridging the gap between laboratory research and full-scale production, the project strengthens both domestic and international capability in scalable, sustainable steelmaking. It will be supported by MPI’s existing secondary refining, ingot and slab casting infrastructure, and world-class laboratories.

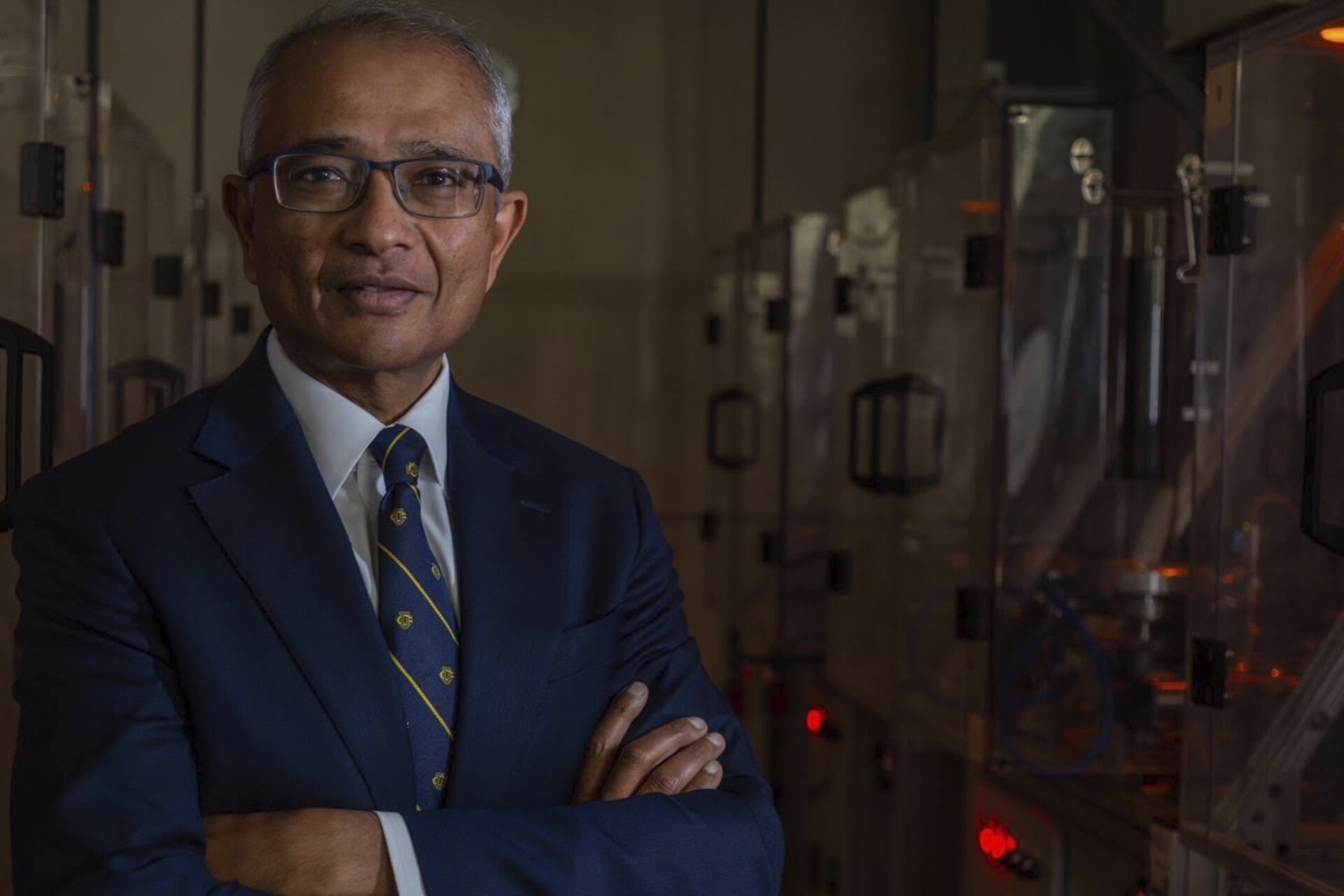

Chris Oswin, CEO of the Materials Processing Institute, said: “This upgrade marks a major milestone for MPI and for the UK’s journey toward commercial-scale low-emission steelmaking.

“It significantly enhances our capacity to develop and demonstrate the technologies needed for future EAF-based production, providing industry with a unique environment to test and prove innovation and bring higher recycled content, high-performance steel grades and technologies to market quicker.

“As installation begins, we are moving into a crucial phase of work that will deliver long-lasting benefits for industrial decarbonisation, competitiveness, and the resilience of the UK steel supply chain.”

The project is supported by Innovate UK, part of UK Research and Innovation (UKRI), through the Foundation Industry Sustainability Consortium’s (FISC) EconoMISER programme – an initiative that provides access to advanced research facilities and specialist expertise to help manufacturers integrate sustainable technologies into their operations.

Work on the upgrade began over 18 months ago, starting with detailed evaluations and technical specifications. Major components – including a new furnace body and platform, electrode masts and arms, control panels, and upgraded charging and hopper systems – are now being delivered to MPI’s Teesside site.

Initial dismantling has already begun, including the removal of refractory materials, the extraction hood, and the existing concrete roof. The current furnace will be removed in January, enabling full installation to proceed, followed by cold and hot commissioning trials.

The upgrade will deliver a suite of advanced capabilities to enhance safety, energy efficiency, feedstock management, and process control, including:

• Jet box powder injection, enabling direct injection into molten steel or slag while powered, improving safety, melt times, and energy efficiency

• HBI/DRI/H2DRI feeder and argon-fed porous plug to support continuous charging and process stability

• Automated, continuous temperature monitoring to enhance efficiency and operator safety

• Carbon injection stand for greater control of carbon inputs and metallurgical performance

• Integrated digitalisation and modelling tools offering real-time monitoring and predictive insights

• Enhanced tapping and slag-removal instrumentation with precise hydraulic tilting capabilities

• Electrode magnetic drives to support faster, more efficient melt cycles

The enhanced pilot-scale furnace will support the development and industrialisation of new green steel grades and slag products, accelerate the shift to EAF-based production, enable the testing of new instruments and steelmaking technologies, and expand MPI’s specialist melting and casting services across key sectors including nuclear, defence, offshore, aerospace, packaging, and advanced engineering.