Fintek to Showcase Advanced OTEC Surface Finishing Technologies at MACH 2026

By Marie Carter-Robb • Posted in Manufacturing

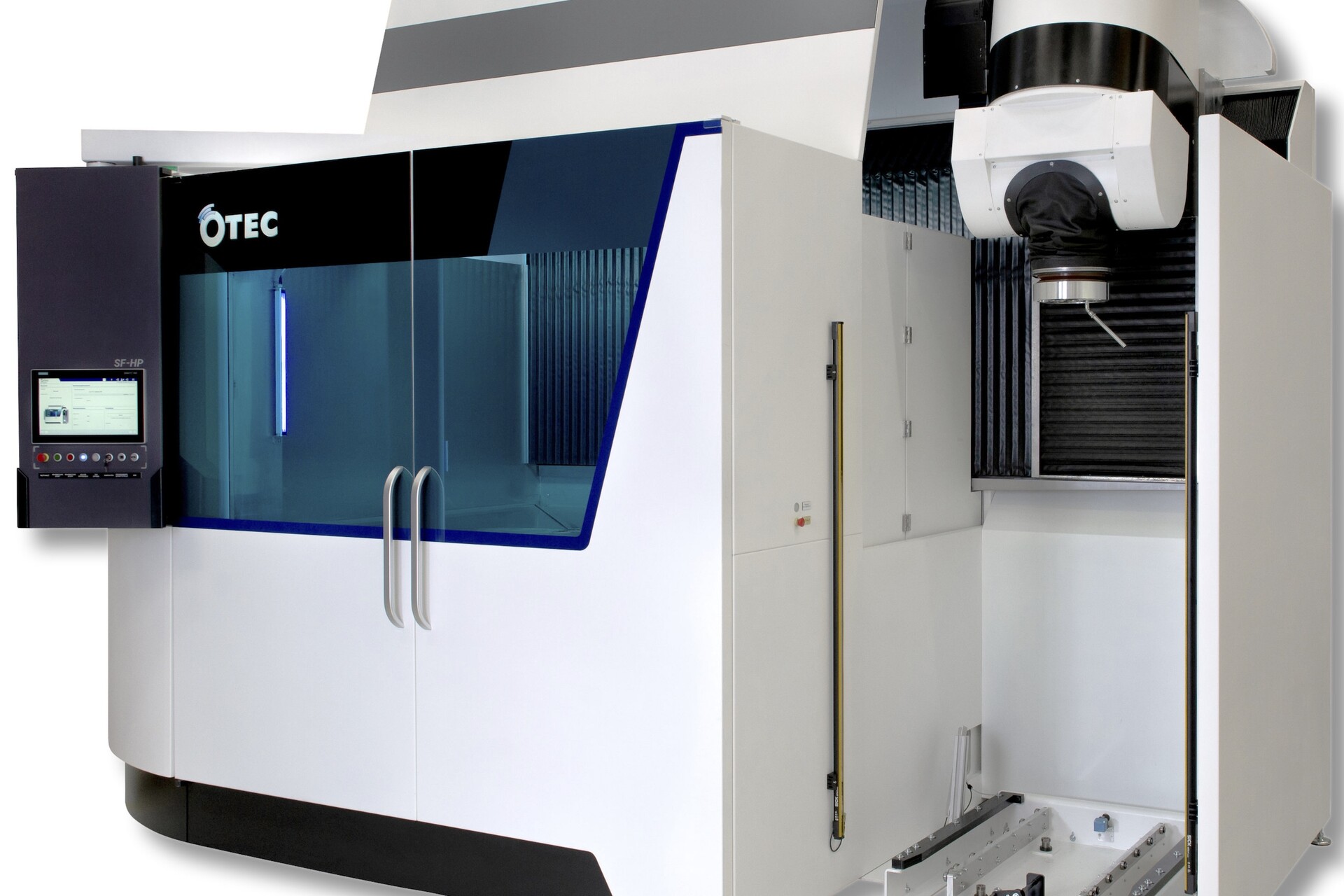

Fintek is set to return to MACH 2026 with an impressive showcase of advanced surface finishing and post-processing technologies on Stand 18-12. Targeting manufacturers with demanding production and quality requirements, the company will highlight high-performance systems engineered for speed, precision, and capacity—alongside innovative tools such as the Orbitool for efficient deburring of cross-drilled holes.

At the heart of the stand will be Fintek’s full range of OTEC Präzisionsfinish machines, for which the company is the UK agent. OTEC is globally renowned for its disc (CF), drag (DF), stream (SF), and electro-finishing (EF) systems—each designed to deliver consistently precise and repeatable surface finishes across a variety of metals and geometries, from the straightforward to the complex.

A key focus for 2026 will be Fintek’s ability to support the finishing of larger components. Stream finishing is now available for parts up to 900mm in length and diameter—meeting growing demand from sectors such as aerospace, motorsport, and advanced tooling, where larger components must still meet exacting tolerances.

Superfinishing and mass finishing will also take centre stage. OTEC’s SF technology delivers high throughput without compromising precision, achieving surface roughness values as low as Ra 0.01µm—often in just minutes. These systems enable manufacturers to meet tight specifications while supporting efficient, scalable production.

Enhancing these capabilities, OTEC stream finishers can be fitted with proprietary Pulsfinish technology. By alternating the rotational direction of the finishing heads, Pulsfinish creates intense relative motion between media and workpiece. Rapid acceleration and deceleration increase finishing forces, resulting in shorter cycle times and superior surface quality—all while preserving critical component geometry.

Automation will be another major theme. Fintek will present a range of automated solutions, from chain-feed loading systems to fully robotised loading and unloading. These options support seamless integration into modern production lines, reduce manual handling, improve process consistency, and enable lights-out manufacturing.

All OTEC machines are Industry 4.0 ready, offering data transparency and connectivity as standard. For manufacturers seeking deeper digital integration, an advanced package is available featuring an industrial PC for real-time machine monitoring, process optimisation, and remote maintenance—maximising uptime and production control.

Fintek will also demonstrate the J.W. Done patented Orbitool, an in-process solution for deburring cross-drilled holes. As traditional off-line methods can disrupt manufacturing flow, Orbitool offers significant time and cost savings—ensuring precision without interrupting throughput.

In addition to machine sales, Fintek provides a comprehensive subcontract surface finishing service. Components are processed in-house for manufacturers in aerospace, motorsport, medical, implant, and general engineering sectors. This service also enables customers to trial and validate processes prior to investing in their own OTEC systems.

Fintek supports all systems from its UK base and operates to ISO9001 and AS9100 standards—reflecting its long-standing commitment to quality and reliability.

Fintek will be exhibiting on Stand 18-12 at MACH 2026. For more information and to register, visit machexhibition.com.