Sector News > Energy & Renewables

ENATS Certification Sparks Surge in Demand for Scott Bros’ Recycled Sand

By Marie Carter-Robb • Posted in Energy & Renewables

Recycling specialists Scott Bros have seen a sharp rise in demand for their recycled sand after achieving ENATS certification – a key quality standard for materials used in energy infrastructure.

The family-run firm, based at Haverton Hill in Billingham, is now ramping up production after supplying several thousand tonnes to solar farms and high-voltage cable installations, where the material is used for bedding and backfilling underground electrical cables.

ENATS – the Energy Networks Association Technical Specification – certifies that the sand meets essential performance, cohesion and safety requirements for solar and grid connection projects.

The sand is processed at Scott Bros’ £6m wash plant in South Bank, Middlesbrough – one of the UK’s largest ‘urban quarries’ – which converts construction and excavation waste into British Standard sand and aggregate. As well as offering environmental benefits, the recycled product is more cost-effective than quarried alternatives.

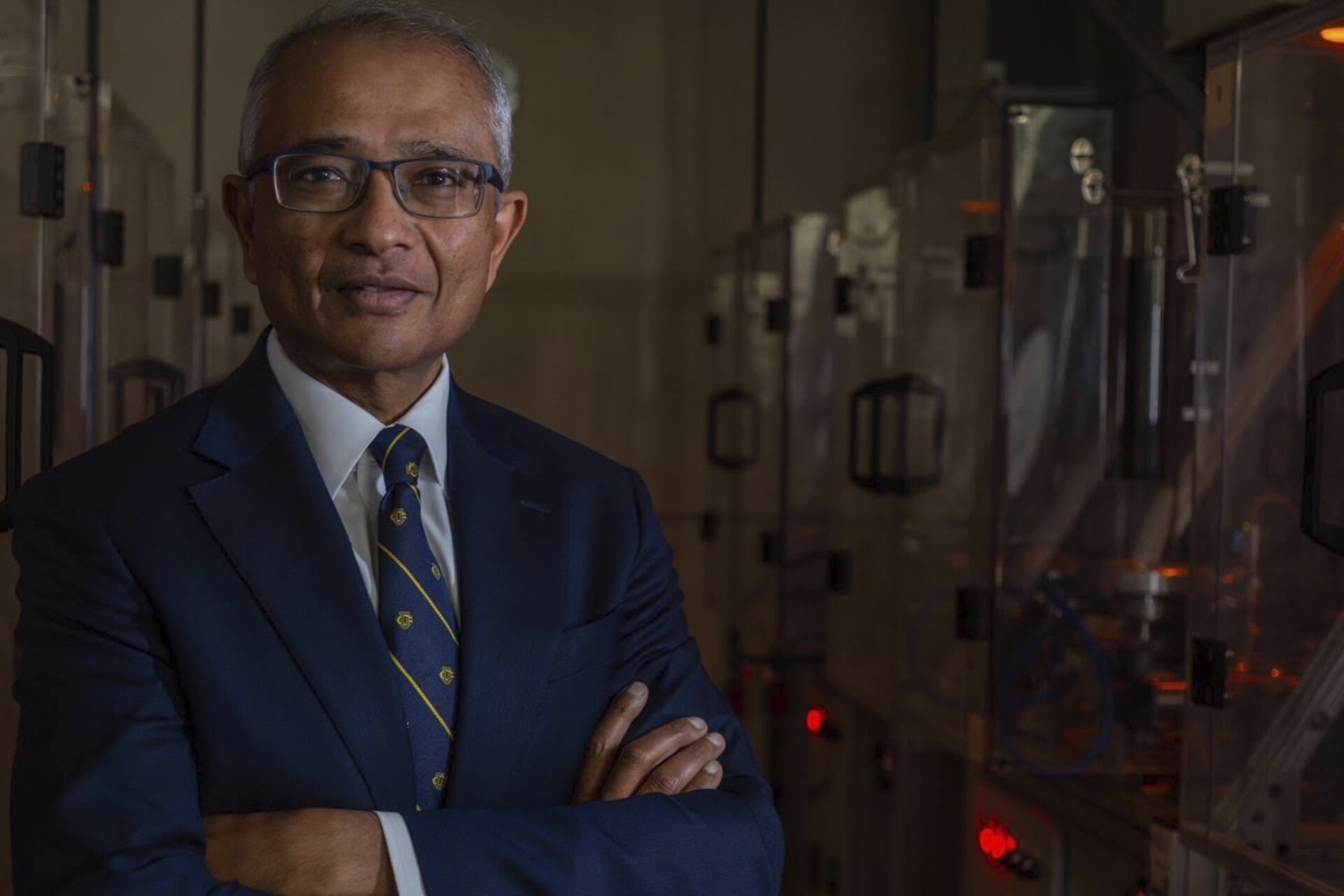

Director Peter Scott, who led the product development, secured ENATS approval by adjusting the mix to increase the ratio of extra-fine particles, improving the material’s cohesion.

“We’re proud to be one of the few local suppliers of recycled sand to meet the ENATS standard,” said Peter. “Solar farm developers need materials that protect high-voltage cables from damage and maintain stable heat transfer. The fact they’ve made a rather large dent in our stockpiles shows the scale of demand for reliable, sustainable alternatives to virgin sand.”

Scott Bros’ recycled building and sharp sands are already widely used – from commercial construction to enhancing golf course drainage, turf health and surface firmness.

Fellow director Bob Borthwick added:

“It’s especially rewarding when you consider that, not too many years ago, the construction and excavation waste now being processed into ENATS-approved sand would likely have ended up in landfill or as low-grade fill. It’s a great example of how recycled materials can replace virgin resources without compromising performance.

"Every tonne we supply saves the equivalent volume of natural sand from being quarried. Renewable energy developments, particularly solar farms, are being built at pace across the UK, and we’re pleased to help the sector cut both its costs and its carbon footprint.”